Chinese New Year to have ‘significant impact’ on supply chains

Chinese New Year to have ‘significant impact’ on supply chains

Freight forwarders and supply chain professionals are expecting disruptions owing to Covid outbreaks in China and this year’s Chinese New Year factory closures.

According to the annual Chinese New Year survey conducted by container logistics platform Container xChange, 73 per cent of supply chain professionals expect the holiday, which began on January 22, to further disrupt the shipping industry this year, as opposed to 66 per cent who said the same thing in 2022.

This comes in contrast to industry reports predicting a reduction in disruptions from China on the global supply chains. Of the 73 percent saying that they do foresee an impact, 65 percent were freight forwarders and the rest were supply chain professionals in general.

“We are looking at three different Chinese Years in 2020, 2021 and 2022. It’s not what we’ve been accustomed to in the prior years when there was demand leading up to the Chinese New Year. There is a lot of inventory with retailers and manufacturers,” said Cathy Morrow Roberson, Founder and President of Logistics Trends & Insights LLC during a webinar organised by Container xChange.

“Inflation and fear of recession continue to impact demand. And therefore, the spot rates have started to fall off the cliff. There are a lot of unknowns and preparing with better data, information and visibility into the supply chain is the way to navigate through these unforeseen times.”

The annual Chinese New Year survey witnessed 2300 respondents from the supply chain industry who were asked to identify how Chinese New Year closures and Covid outbreaks impact global supply chains.

TIME-TESTED STRATEGY

Ordering inventories in advance is still the time-tested strategy to future-proof disruptions caused by Chinese New Year shutdowns, experts suggest.

“Usually, we expect a cargo rush in January and February but this year, the Chinese New Year is earlier. The situation will have a significant impact on the domestic supply chain from January 15 to February 6, 2023. In my opinion, this time is difficult for businesses. I think companies can prepare better by controlling costs, better forecasting, and efficient information flow. This is where technology can help greatly,” suggested Sun, Director / General Manager, CNTRANS in the webinar.

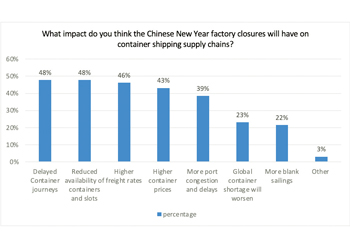

The survey found supply professionals anticipated port congestion was going to be most impacted from the celebrations. The respondents said the impacts they expect will include “an increase in port congestions and delays” and “delayed container journeys” soon after China reopens. That contrasts with last year’s survey results, when most industry professionals feared capacity issues and higher rates as the holiday’s aftermath.

“There are added, and new complexities ahead coupled with Chinese New Year where at one end we see China coping with the Covid infections, and on the other end we see a continued dip in demand. We cannot see Chinese New Year in isolation but in combination with all these challenges,” said Christian Roeloffs, cofounder and CEO, of Container xChange.

“The biggest concern is the reduced production and port capacity due to the infections in China. Also, the rates are low, capacity management is still a top priority for carriers and blank sailings are prominent. Amidst this, in the coming weeks, we foresee prolonged factory closures and bearish market conditions,” he added.

NEW YEAR CLOSURES

In terms of preparation for New Year closures, 59 per cent of respondents said they had prepared for Chinese New Year by ordering early in the year 2022.

While the majority planned advance bookings, there is a drop of 4 per cent. Another change noticed this year was, while 65 per cent of international freight forwarders said they expect Chinese New Year closures to impact supply chains, only 47 per cent said they have made advance plans to deal with the same. One possible cause of the dip in preparing in advance could be still high inventory levels—and the market being bearish in general, as demand continues to fall and transportation capacity supply increases.