Rockwell Automation, one of the world's largest companies dedicated to industrial automation and digital transformation, said it has helped Dubai-based Falcon Group to boost its machine utilisation by 162.5% with the help of its key industrial internet of things (IIoT).

According to Rockwell, this was done through deployment of its ThingWorx IIoT platform, a part of the FactoryTalk InnovationSuite, powered by PTC.

Headquartered in Dubai, Falcon Group comprises five industrial operations. One of these is a specialist precision engineering and fabrication company that caters for the demanding needs of customers in the aerospace, automotive, marine, healthcare, defence, oil and gas, and steel industries.

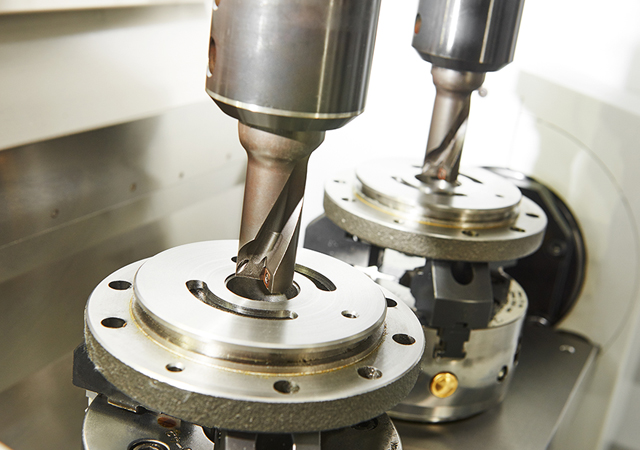

At the heart of its operations are 16 CNC machines, all of which are essential to the company's machining capabilities.

Before support from Rockwell Automation, Falcon was considering purchasing additional CNC machinery to keep pace with customer demand and to support maintenance downtime for critical machines.

When at peak capacity, to meet order dates, the company had subcontracted work to competitors. But before signing off on additional machinery, the company decided to assess its current asset utilization.

Falcon Group CEO Prabhu Badrinathen said: "We are always looking for ways to do things better and deliver even greater levels of service to our customers. We knew we had room to grow our machine utilization, but it was not until we got the real-time, machine-level insights from the ThingWorx platform that we realized where inefficiencies were and where the changes needed to be made."

"We have grown our utilization from 16% to 42% and have set an ambitious future target of 75% – a growth of more than 365%," noted Badrinathen.

"ThingWorx has this incredible capability to bring operational data together in such a way that it offers immediate value in the form of actionable intelligence," he added.

Mohamed Elnakib, the Head of information solutions sales, Middle East, Turkey and Africa for Rockwell Automation, pointed out that Badrinathen was very digital savvy and understood that digital transformation could deliver huge benefits to his people, his assets, and his processes.

"Using ThingWorx, part of FactoryTalk InnovationSuite, connected to PLCs and sensors throughout the plant, we were able to ascertain that machine utilization was sitting at only 16%," he added.

Rejin Jose Kurian, the managing director at Falcon Group, said the increase in machine utilization – and the new business opportunities created – demonstrates the company's commitment to continuous improvement and innovation.

"We were always a very successful company, but we also knew we could do more," remarked Kurian. "We challenged the team to think about what was possible and how we can grow the business," he stated.

Sebastien Grau, the Regional Vice President, Middle East, Turkey, Africa, Rockwell Automation, said: "Falcon management perfectly embraces the potential of industrial software and the benefits they have seen are a great example of a successful digital transformation."

"With a pragmatic step-by-step approach, Falcon delivers tremendous process and cost improvements but even more, Falcon is opening new doors for additional business by becoming a Rockwell Automation software system integrator and sharing their expertise and knowledge," he added.-TradeArabia News Service