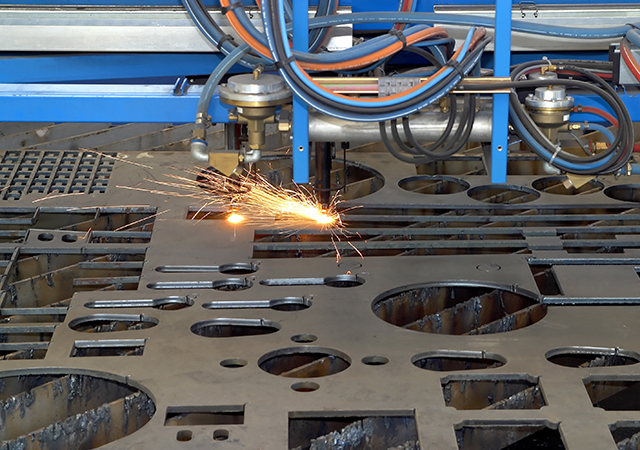

Image by Paripat Niyantang BigStock

Image by Paripat Niyantang BigStock

As the world grapples with the urgent need to tackle climate change, the steel industry has found itself squarely in the crosshairs. Responsible for around 5 per cent of CO2 emissions in the European Union (EU) and 7 per cent globally, the steelmaking sector is under mounting pressure to transform its production processes and embrace greener technologies, according to a report by Fastmarkets.

The EU ambitious goal of becoming a net zero-emitter by 2050 has galvanised the region's steel producers into action. Faced with the looming specter of the Carbon Border Adjustment Mechanism (CBAM) and the phasing out of free carbon allowances, European steelmakers are exploring a range of alternatives to the traditional blast furnace route, which currently accounts for 60 per cent of regional production.

THE SHIFT TO LESS POLLUTING PATHWAYS

The electric arc furnace (EAF) and direct reduced iron (DRI) production routes hold significant promise as more environmentally friendly options. With direct and indirect CO2 emissions estimated at around 1.4 tonnes per tonne of steel, the EAF-DRI pathway is a far cry from the 2.0-2.2 tonnes of CO2 associated with the integrated blast furnace/basic oxygen furnace (BF-BOF) route.

The scrap-based EAF process, in particular, stands out as the greenest option, with just 300 kilograms of CO2 per tonne of steel. This production method has the potential to achieve net-zero emissions when powered by renewable energy sources, states the report.

However, the transition to these less polluting routes will require a fundamental rethinking of the industry's raw material supply. Europe, currently a net scrap exporter, may need to become an importer of certain grades as new EAF-based capacities come online, driving increased demand for high-quality scrap.

FUELING TRANSITION: CRUCIAL ROLE OF GREEN HYDROGEN AND RENEWABLE ENERGY

Unlocking the full decarbonisation potential of the steel industry will hinge on the availability of sufficient green hydrogen and renewable energy. Europe faces a significant challenge in this regard, with the sector's additional energy requirements estimated to reach around 400TWh of CO2-free electricity by 2050 – a sevenfold increase from current levels.

The EU has set ambitious targets for renewable hydrogen production, aiming for 6GW of electrolyzer capacity by 2024 and a staggering 40GW by 2030. However, the current high cost of hydrogen, with prices ranging from €5-8 ($5.44- $8.70) per kilogram, presents a significant hurdle. Industry experts suggest that hydrogen prices need to be at least €2.5-3 per kilogram to be commercially viable for steelmaking, said Fastmarket.

Overcoming these challenges will require a coordinated effort between policymakers, energy providers, and the steel industry to rapidly scale up renewable energy infrastructure and drive down the costs of green hydrogen production.

EVOLVING GREEN STEEL MARKET: DEMAND, PREMIUMS, AND REGULATION

As the steel industry embarks on its green transformation, the market for low-emission steels is beginning to take shape, albeit with some growing pains. Demand for green steel has been sporadic, with many buyers reluctant to pay the significant premiums associated with these products.

Fastmarkets' assessment of the green steel differential in Northern Europe stood at €150-250 per tonne in February 2024, underscoring the significant cost premium. However, some industries, such as automotive, have shown more interest in securing long-term contracts for green steel deliveries, signaling a potential shift in the market.

The lack of a clear regulatory framework and common understanding of what constitutes "green steel" has been a significant barrier to widespread adoption. The European Commission's efforts to provide clarity and stimulate demand, such as the impending CBAM and the phasing out of free carbon allowances, are expected to play a crucial role in driving the green steel transition, according to the report.

At the same time, some steelmakers have turned to a more incremental approach, offering "reduced carbon emission steel" produced via the traditional BF-BOF route, with more "digestible premiums" compared to the "fossil-free" EAF-based offerings. Fastmarkets' new assessment of the flat steel reduced carbon emissions differential, at €40-60 per tonne, reflects this emerging market segment.

ROAD AHEAD: NAVIGATING CHALLENGES, SEIZING OPPORTUNITIES

As the European steel industry embarks on its green transformation, a myriad of challenges and opportunities lie ahead. Securing reliable and affordable supplies of green hydrogen and renewable energy, developing new production technologies, and navigating the evolving green steel market will all require strategic foresight and collaborative efforts, claims the report.

The implementation of CBAM and the phasing out of free carbon allowances under the EU Emissions Trading Scheme will undoubtedly drive further change, with industry experts projecting a significant jump in carbon prices to €200-250 per tonne by 2034.

Despite the daunting task, the European steel sector has demonstrated its resilience and innovation in the past. By leveraging the latest technological advancements, forging strategic partnerships, and embracing a holistic approach to sustainability, the industry can chart a pathway to a greener, more competitive future.

As the world watches closely, the steel industry's journey towards decarbonisation will undoubtedly serve as a blueprint for other carbon-intensive sectors seeking to navigate the complex and ever-evolving landscape of environmental regulations and market demands. The race to green steel is on, and the stakes have never been higher.