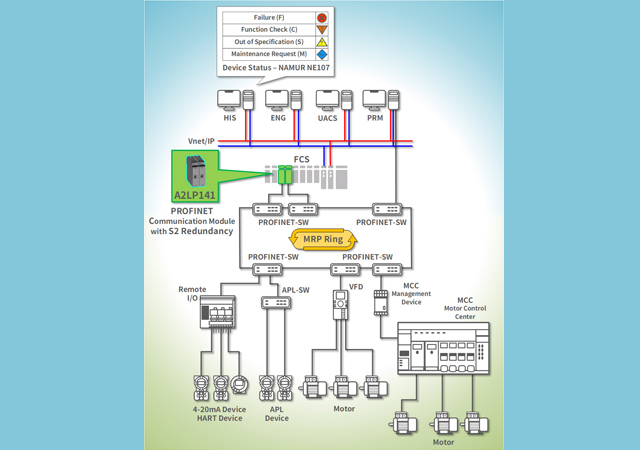

System architecture of CENTUM VP PROFINET

System architecture of CENTUM VP PROFINET

Yokogawa Electric Corporation announces the release of CENTUM VP R6.11.10, an enhanced version of the CENTUM VP integrated production control system that is a core product in the OpreX Control and Safety System family of solutions.

With this new version of CENTUM VP, plant uptime is improved through the addition of a redundancy function to a new IO card that supports communications via the PROFINET communications protocol for industrial networks.

Furthermore, to reduce project costs and improve efficiency in plant operations, functional enhancements have been made to the Unified Alarms and Conditions Server (UACS) and the CCC Insidefor the Yokogawa CENTUM VP compressor control solution.

DEVELOPMENT BACKGROUND

PROFINET is one of the most widely used Ethernet-based industrial communications protocol worldwide, boasting superb real-time performance.

In 2019, Yokogawa developed an IO card that supports PROFINET. While this enabled the monitoring of the operation of PROFINET-compatible devices from CENTUM VP, more needed to be done to improve reliability and uptime.

To meet this need, Yokogawa has developed a new PROFINET IO card that supports a redundancy function, and by doing so, has made high reliability and high uptime a reality.

This new CENTUM VP release also features functional enhancements to the UACS and the CCC Inside for the Yokogawa CENTUM VP compressor control solution that will improve the efficiency of operations and engineering at plants.

PRODUCT FEATURES

•PROFINET IO card redundancy support for greater reliability and increased uptime:

To improve plant uptime, an S2*1 redundancy function has been added to the new PROFINET IO card, enabling its use in a redundant configuration.

Thanks to this and enhancements that have been made to the card's network diagnostics function, this device has been certified by a third-party agency as having all the PROFINET functions for Conformance Class*2 B (CC-B), including the system redundancy that is so important in process control.

By supporting the use of NAMUR NE107*3 compliant self-diagnostic information from devices that support PA Profile 4.0*4 and enabling the use of a motor control center that centrally controls motor power sources, remote I/O and Ethernet Advanced Physical Layer (Ethernet-APL) compatible device operation monitoring are also now possible, and this expands the scope of control that is possible with a single control system.

•Improved plant operational efficiency with alarm management that supports NAMUR NA102: When a specific alarm has been suppressed in the UACS, the suppression status can now be displayed in the Human Interface Station (HIS) graphics. By enabling the implementation of alarm management in compliance with NAMUR NA102*3, this can help to improve operational efficiency throughout a plant.

•Seamless integration of process and compressor control systems: It is now possible to undertake integration and engineering using a single CENTUM VP project database for the process and compressor control systems.

This release of CENTUM VP also enables process and compressor control systems to be connected to a Vnet/IP*5 control network within the same domain.

As such, this allows highly seamless system integration and helps to reduce project and maintenance costs.

KEY MARKETS

Key markets include oil refining, petrochemicals, chemicals, electric power, pulp and paper, gas, pharmaceuticals, food, iron and steel, water supply and wastewater treatment, non-ferrous metals, metal, cement, etc.