The front horizontal tube will soon be replaced by the 3D-printed version

The front horizontal tube will soon be replaced by the 3D-printed version

If Dr Senada Schaack has her way, the chemical reactor of the future will be small, custom-tailored, and homemade. “It’s disruptively different,” says Schaack, a process engineer who is researching a new generation of minireactors for Evonik in Hanau, Germany. The metal contraption is only about as big as a shoebox, but it promises great advances. Its abilities aren’t apparent from the outside. However, its inner workings are designed so that a chemical synthesis requires as little energy as possible and causes less CO2 emissions. Some reactors contain extremely thin tubes through which the reaction mixture or a cooling medium can be pumped during operation. Others contain intricately branched systems, which help to distribute flows from one tube to several.

|

|

Dr Hendrik Rehage |

“If we do this well, we can achieve a high degree of purity in the desired product and save energy that previously had to be used for cooling or complex material separations, such as distillation,” explains Schaack, who runs the Simulation and Additive Manufacturing competence center, or SAM 3D for short. Together with her employees, she develops concepts for the design of reactors—and then manufactures them from stainless steel powder using 3D printing.

COOL INSTEAD OF ICE-COLD

Ortho-lithiation, for which the 3D-Process team in Hanau is developing a reactor, is a case in point where a lot of energy can be saved with a better design. In this synthesis step, a lithium atom is temporarily introduced into an organic molecule. This releases so much heat that the reaction vessel has to be cooled down to at least minus 50 degrees Celsius. This technique uses liquid nitrogen, which requires a lot of energy to produce. A cooling temperature of -20 degrees Celsius could be sufficient for the new approach with the small metal block. The cooling could be carried out with an electrically temperature-controlled liquid, which would reduce energy consumption by 80 percent compared to the nitrogen variant.

|

|

Senada Schaack inspects the ortho-lithiation apparatus |

The enormous savings are made possible by the innovative design of the reactor. It differs significantly from the conventional tank reactors commonly used in the chemical industry. In the latter reactor, the reaction heat is dissipated by cooling coils in the interior or in the double-walled outer shell. Because the cooling surface is relatively small in relation to the reactor volume, the cooling medium has to be very cold. The new reactor is a much smaller system known as a flow reactor. In the simplest case, the reaction mixture is passed through a linear reaction tube, which is wrapped in a cover containing the cooling medium. The ratio of the cooling surface to the reactor volume is significantly larger, which means that the medium does not have to be that cold. The heat dissipation becomes even more effective if the reaction mixture is not just passed through one tube but distributed over several channels.

COMPLEX STRUCTURES

This is exactly how the experts at Evonik designed their micro reactor. “In the first prototype, we distribute the flow of the reaction mixture over a total of 256 tubes,” explains Dr Hendrik Rehage, a process engineer on Schaack’s team. The advantages are obvious: More tubes increase the flow rate while making cooling more efficient at the same time, because each tube is surrounded by its own cooling channels. The experiments are intended to show whether the cooling temperature of -20 degrees Celsius calculated on the computer is actually sufficient. The 256 reaction channels are each 0.8 millimeters in diameter. With conventional methods of metal processing, this would be an immense effort or not possible at all. But the situation is different when you use a 3D printer. “It doesn’t matter at all whether we manufacture a reactor with one or 256 channels,” says Rehage, explaining why additive manufacturing also makes very complex reactor geometries accessible.

The decisive advantage of 3D printing compared to the classic production of microreactors is that the printed items can have any shape. Luckily, it’s long been possible to carry out 3D printing with metals such as aluminum, titanium, and stainless steel. The metal is fed in in finely powdered form, melted by a laser beam, and then deposited layer by layer on the workpiece to be manufactured.

A SELF-OPTIMIZING SYSTEM

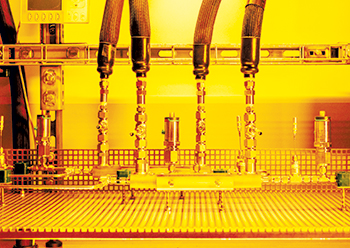

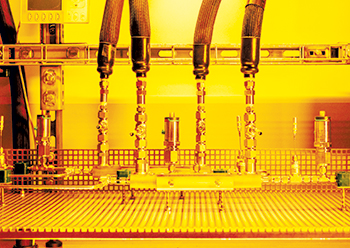

|

|

The heart of the test apparatus |

This was the case with the first prototype for ortho-lithiation. The team wants to use the possibilities of 3D printing to provide the components with integrated connections for the installation of sensors. These record temperatures, pressures, flow rates, and substance concentrations during operation.

“This data lets the system know whether it is getting too hot somewhere in the reactor or whether unwanted byproducts are being produced,” explains Rehage. “On the basis of the sensor data, the system is able to adjust the process control and thus gradually get closer to optimal conditions in a self-learning loop,” explains Schaack.

If this optimum cannot be achieved with the existing reactor, the data provide information on how the design should be changed, Schaack adds. Dr Stefan Randl is also enthusiastic about such visions. As the head of research in the Health Care business line, Randl is following the experiments with the test reactor with great interest. He considers ortho-lithiation to be “a model example for many other syntheses in the pharmaceutical environment that previously had to be cooled or heated with a great deal of energy.” Evonik produces active pharmaceutical ingredients and their precursors for external customers. It often happens that Randl’s team still has to develop the associated synthesis process.

GREEN HYDROGEN

|

|

The monitor shows an experimental design for ortho-lithiation |

However, the printed micro reactors should also bring their disruptive properties to bear in other areas. In another subproject of 3D-Process, Evonik is working with researchers from the Karlsruhe Institute of Technology (KIT), Siemens Technology, and the KIT spin-off INERATEC. The partners are working on a reactor for the conversion of hydrogen and carbon dioxide (CO2) into methanol or dimethyl ether. Both substances are important basic chemicals and can also be used as fuels. While the CO2 comes from biogas or exhaust gases, the hydrogen can be obtained through water electrolysis – preferably when excess renewable electricity is available. A corresponding reactor must be simple and robust and also meet a number of requirements, one of which is to separate the resulting methanol directly from the reaction mixture. In fact, 3D printing allows defined porous structures in the reactor wall. Thanks to these structures, this can now be achieved in connection with a suitable temperature control.

FROM THE IDEA TO THE REACTOR

Initial trials in a test reactor have been promising. When all the small-scale studies are complete, the consortium will start to develop design rules to scale up the reactor to an industrial scale. Professor Christoph Klahn, who works on additive manufacturing in process engineering at KIT, praises the acceleration of the development process. “Thanks to the well-prepared design and manufacturing workflows, we can produce the corresponding experimental reactor for every new idea within two days,” he says. The software modules for these end-to-end workflows come from Siemens and include simulation, design, and digital control of the 3D printers for reliable production of the fine structures. Dr Christoph Kiener, Principal Key Expert Functional Design at Siemens, says than the 3D-Process research project is an important contribution to the energy transition. He thinks that the new possibilities will transform the concept of chemical reactors.

3D-PROCESS

The project “Disruptive reactor concepts by means of additive manufacturing: From the digital design to industrial implementation—3D-Process” kicked off in June 2021 and will conclude in May 2024. It has a budget of €9.8 million and is funded as a joint project by the Federal Ministry for Economic Affairs and Climate Action under the funding code 03EN2065A-E. The consortium leader of the project is Evonik. Other partners include Siemens, the Karlsruhe Institute of Technology (KIT) with the Institute of Catalysis Research and Technology, the Institute for Chemical Technology and Polymer Chemistry, and the Institute for Micro Process Engineering, as well as INERATEC. The aim is to develop process engineering components for more energy-efficient chemical processes that cause fewer emissions and are more sustainable.