EBS has executed landmark projects in the UAE

EBS has executed landmark projects in the UAE

A company with a notable usage of more than 850,000 tonnes of steel for 6,200 projects in more than 50 countries, Emirates Building Systems (EBS)’ contribution to the UAE's industrial growth / manufacturing sector is more than apparent.

Established in 1997, as a subsidiary of Dubai Investments, it has successfully completed 25 years in steel business, and is now further strengthening Dubai Investments business portfolio in the steel business across the region and globally.

|

|

Joseph Chidiac |

Today, one of the leading manufacturers of steel structures in the Middle East, apart from being the market leader in UAE, says it will continue to evolve with the region’s growth requirements, contributing to the “Made in the UAE” portfolio of products.

“The company will continue to evolve with the region’s growth requirements and focus on maintaining a growth trajectory, contributing to the “Made in the UAE” portfolio of products, thereby enhancing the manufacturing sector,” Joseph Chidiac, General Manager, Emirates Building Systems told the Gulf Industry while commenting on how EBS is contributing to the UAE's new industrial strategy Operation $300bn.

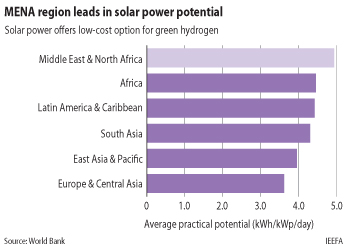

EBS has established a significant international presence in Middle East, Africa and Asia and has executed thousands of projects to cater an extensive client base across the globe. Currently more than 40 per cent of the company’s products are exported to Africa and Asia markets.

“As the UAE's industrial activities within the manufacturing sector continue to rise, and the country arrives closer to achieving sustainable diversification as per its Economic Vision 2030, we pride in being a part of its ongoing success story,” he said.

“We at EBS take pride as one of the leading manufacturers of steel structures in the Middle East, as well as being the market leader in the UAE. We maintain an impressive portfolio of completed projects including Dubai World Central International Airport’s cargo terminal and passenger terminal, Dubai Metro, Dubai prosecution new building, UAE’s first Waste to Energy Plant in Sharjah, power plants, pharmaceutical plants, various factories and logistic centers, high rise buildings with more than 50 stories, oil and gas pipelines and refineries, etc. All these projects have contributed significantly to the UAE’s GDP,” Chidiac said.

“In addition, our EBS factories, located in the UAE, produce thousands of tonnes of steel annually and we are constantly looking at new and improved ways to increase production and meet local and international demands,” he added.

The company’s facilities extend over an area of 140,000 sq m with an annual fabrication capacity of more than 75,000 tonne.

SILVER JUBILEE HIGHLIGHTS

Capitalising on the technical expertise and an expanded product portfolio, EBS silver jubilee highlights underline a projects portfolio includes high-rise buildings, airports and metro railways, power plants, refineries, oil and gas structures, factories, bridges, logistics and distribution centers, warehouses, theme parks, poultries and dairy farms and car parks.

|

|

UAE’s steel demand has made it one of the largest consumers in the GCC region |

According to him, EBS maintains stringent quality management standards across its internal systems and processes. Its commitment to quality and environmental standards has been recognised with ISO 9001:2015, ISO 14001: 2015, ISO 45001:2018 and CE marking certificate, he added.

“As EBS makes its foray into regions beyond the Middle East, we are drawing upon its reputation as one of the UAE’s leading manufacturers of steel structures and in addition to our business in the UAE and the Middle East countries, more than 40 per cent of our products are exported to Africa and Asia markets, which hold immense potential and are lucrative markets for the steel business,” Chidiac said.

The latest design, drawings and construction software’s in line with international codes and standards are used by the engineering and the projects teams.

Advanced technologies are utilised in factories throughout all stages of the manufacturing process starting from the cutting of the steel, fitting and welding activities till the painting lines and finished products, he stated.

EBS has sales offices and agents in Ethiopia, Ivory Coast, Ghana, Nigeria, Uganda, Angola Algeria, Pakistan, Uzbekistan, Georgia, and Armenia to cater to an extensive client base across the globe.

“Our growth in African and Asian markets will continue by opening new sales offices and appointing new agents and builders. We have made strategic business plans to expand and explore these opportunities and are expecting more than 75 per cent of our business from these regions in the coming 2 years,” he added.

PROJECTS PORTFOLIO

In addition to its projects in UAE, EBS has executed landmark projects in the region. These include depots for the Riyadh Metro in Saudi, 218 meters skyscraper for al Tijariya Tower in Kuwait, 25 & 47 storeys’ Towers in Bahrain, Bahrain Mall, SUR IPP Power plant and shopping malls in Oman, Mazoun Dairy in Oman, steel structures in Duqum refineries, Duqum integrated power and water plant; QSTec Polysilicon project in Qatar, etc.

EBS was awarded several projects in these countries recently including Calcined Petroleum Coke (CPC) Plant in Sohar Free Zone, Oman; utility assets and infrastructure project in Red Sea KSA, King Salman International Complex in KSA; Olympic Resort in Cyprus, etc.

Some of the projects which are being executed by EBS today include: power plants in Sheikh Mohammed Bin Rashid Solar Park, Dubai; Jafza Logistic Parks at Jafza South Dubai; warehouses and offices at Tawazun Industrial Park, Abu Dhabi; beverage factory, Ethiopia; hospitals and transport and logistic facilities in Abidjan, Ivory Coast; aircraft hangars in the New Ouagadougou Donsin International Airport in Burkina Faso, Africa; a pharmaceutical factory, Ghana; and tiles factories, Pakistan.

“Additionally, some local and international major projects are at the final stage of negotiations, which will be signed in the last quarter of this year,” he added.

CHALLENGES

Reflecting on the key challenges and difficulties the company faces, Chidiac said that one of its biggest challenges was receiving steel supplies on time because of its reliance on suppliers from across the world. “Covid-19 brought international supply to a brief halt, while social distancing guidelines interrupted the flow of ships being docked,” he noted.

The main challenges facing the steel industry today, he pointed out, are overcapacity, high raw material/energy costs and price volatility, stiff competition and limitations on automation.

“Regardless of these obstacles, we see a promising future for the steel industry. With preplanning, sound inventory management and the easing in social distancing measures globally, we managed to thrive even during times of difficulty. And as Covid-19 has slowly become the new normal, the industry is rapidly recovering from losses incurred,” he added.

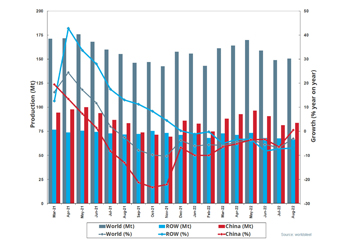

So what prospects does he see for the industry in the next two to three years? “Steel is a major component in buildings, tools, automobiles, and appliances, hence making steel consumption an important indicator of economic growth and prosperity. GCC steel production is fairly fragmented, and UAE's steel demand has made it one of the largest consumers in the GCC region.”

According to industry reports, the global steel market is expected to grow in future owing to increasing infrastructural activities and rising adoption of steel in automotive, electrical, and other end-use industries.

The factors such as rising population growth, growing urban population, growing automobile sector, growing spending on construction and infrastructure projects and growing demand for long steel are expected to drive the market. However, the growth of the industry will be challenged by price volatility, Chidiac noted.

In 2022, steel demand will see further growth of 2.7 per cent to reach 1.925 billion mt, according to World Steel Association, which represents around 85 per cent of global steel production.

Going forward, the company’s focus in 2022 and beyond will be to increasing its sales and turnover, maintaining its services to its clients and make profits for the shareholders.

“We are continuously working to increase productivity at our manufacturing facility by reviewing our existing workflow, updating our processes and technology; organising the workspace; committing to scheduled maintenance, training and educate our employees and maintaining optimal inventory,” he said.