EcoLine 3690 in action

EcoLine 3690 in action

Cortec offers two viable rust preventatives that allow users to go as high as 72% or 99% biobased content for metals protection in humid environments.

EcoLine 3690 and EcoLine 3220 are two wet film rust preventatives from Cortec Corporation. Each includes a special package of corrosion inhibitors in a canola oil base for protection in high humidity conditions.

EcoLine 3690 contains 72% USDA certified biobased content. EcoLine 3220 goes even higher; it contains 99% USDA certified biobased content. Both can be applied by spray, brush, or dip like traditional wet film rust preventatives, leaving behind a tenacious oily film that clings to metal surfaces and provides excellent contact corrosion protection.

Where to Use EcoLine 3690 and 3220

These two temporary biobased coatings can be used in a variety of applications. Among the most common is rust prevention in various stages of the manufacturing process or during storage and shipment.

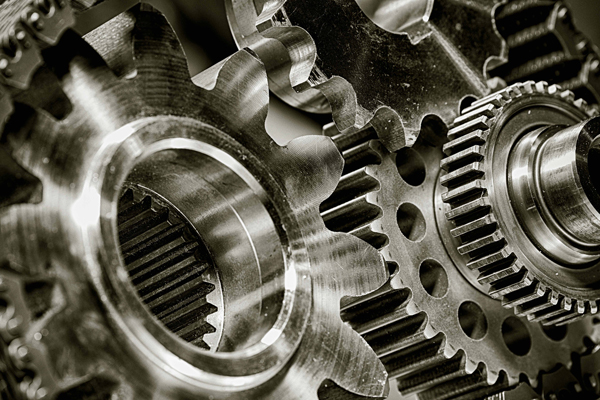

EcoLine 3690 and EcoLine 3220 protects both ferrous and yellow metals and can be applied to wire, sheet metals, pipes, flanges, gears, and equipment. Furthermore, a low pour point of -0 °F (-18 °C) makes EcoLine 3220 good for application in cold conditions where other rust preventatives might freeze.

Biobased rust prevention in action

With almost three-quarters of its content coming from a renewable cooking oil, EcoLine 3690 has been used to replace products that were less friendly to workers and the environment.

In one case, a tube manufacturer investigated the use of EcoLine 3690 as a rust preventative for the ends of pipes bundled and stored for 9-12 months outdoors. They were impressed with the results on the test bundle after eight months and expressed satisfaction with its level of worker safety as they decided to use it going forward.

In another case, EcoLine 3690 was adopted for protection of automotive all-time-buys that needed be stored for up to 10 years after tooling retirement. The previous rust preventative had been used for decades but was hard to remove and raised worker and environmental concerns.

EcoLine 3690 underwent necessary testing and met the automaker’s requirements for rust prevention, so it was written into the automaker’s specifications for aftermarket engineering processes. The third-party packager started using it in 2019 for crankshafts, camshafts, and cylinder heads going into long-term storage.

Being able to reduce the amount of petroleum-based solvents in a product and replace them with gentler biobased material such as canola oil is a great option whenever an effective, affordable product results. With EcoLine 3690 and 3220, manufacturers have two viable options for upping their biobased content and protecting metals from corrosion.--TradeArabia News Service