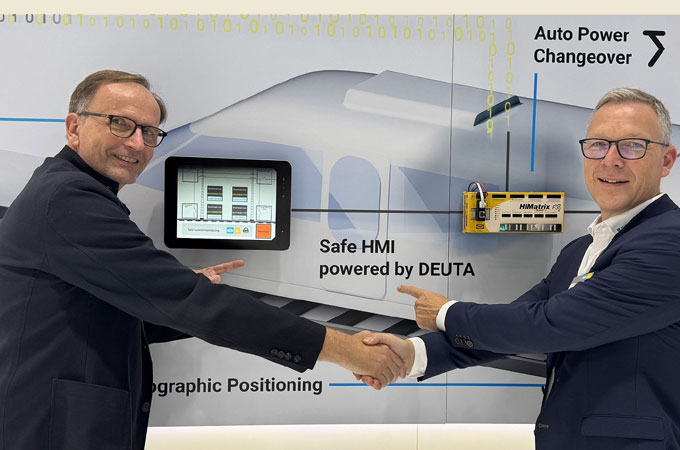

HIMA, a leading provider of safety-related automation solutions based in Germany, and Deuta, a specialist in certified display and safety technology, have jointly launched a new solution, SafeHMI, that combines its safety systems and function block libraries with a safety-related human-machine interface (HMI) panel based on IconTrust technology.

The innovative solution sets new standards in safety-related visualization, offering context-sensitive alarm management, safe operation and display monitoring in accordance with SIL 3 (IEC 61508) and has been consistently designed with an aim to meet functional safety requirements.

While classic Scada systems and Mimic panels often reach their limits in safety-critical applications, SafeHMI delivers clear, prioritised information – exactly where it is required.

"With Deuta, we have a technology partner with decades of experience in the field of safety-related displays, especially in the rail and transport sectors," said Jörg de la Motte, the CEO of the HIMA Group. "With SafeHMI, we are creating a solution that makes functional safety in the industrial environment visible, controllable and digitally manageable," he stated.

Dynamic alarm display, secure input processes

At the heart of the system is the dynamic alarm display, which reduces the burden on operators during fault situations, said the German group in a statement.

Relevant alarms are automatically prioritized, along with concise instructions for action and limited to a maximum of four simultaneous entries. This ensures that an overview is maintained, even in critical moments and operating errors are avoided, it stated.

The solution allows to make inputs, acknowledgements or safe overrides directly through the touch panel – tested, documented and validated according to SIL 2/3. This means that maintenance functions or recipe changes can be carried out digitally and documented in an auditable manner.

Bernd Schäfer, Product Manager at HIMA, said: "With SafeHMI, we are taking display and operating logic to a new level of safety. In critical situations, operators not only receive information, but also clear instructions for action and they can rely on what they see being accurate."

Display with a guarantee of reliability

A key safety feature is the IconTrust technology developed by Deuta. It continuously monitors screen content and reliably detects any deviations between the displayed and expected values.

This makes the display itself an active safety element that is certified up to SIL 3 , offering operators maximum reliability.

Dr Rudolf Ganz, the CEO of the Deuta Group and Deuta-Werke, said: "In partnership with HIMA, we can now provide generic safety technology for operating and display units used in the railway sector with over 30,000 units for new fields of application for which no comparable solution has been available to date."

"In combination with the HIMA safety system, the application possibilities are almost limitless," he added.

The SafeHMI solution is fully integrated into the HIMA Safety Platform. Configuration, modifications and enhancements are carried out using standardized function blocks, which are offered as part of a certified library.

This makes SafeHMI an important component of HIMA’s #safetygoesdigital initiative, with which the company is driving digitalizing of the entire life cycle of safety-related systems and their peripherals.-TradeArabia News Service